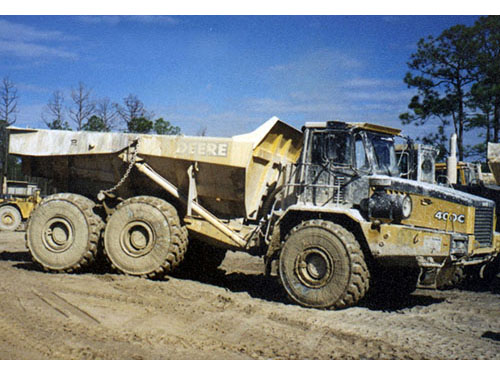

Articulated Tailgates

PHIL's Autogate® Tailgate works with your off-highway articulated truck insuring full truck utilization. Designed to cap off the back end of the truck body, the PHIL Autogate Tailgate contains most any material no matter what they include or road condition. High-Strength steel is used throughout our patented design that allows for minimal weight with maximum durability and effortless operation: the body dumps, the tailgate opens, which makes the PHIL Autogate Tailgate An Investment Worth Making.