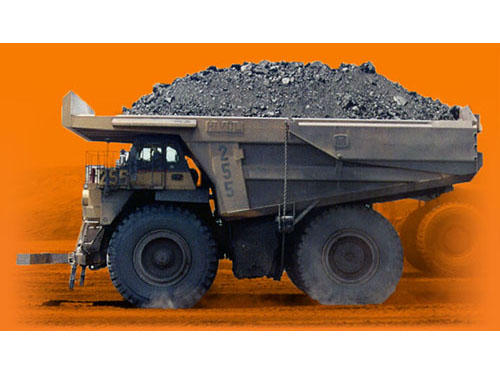

HiVol® coal specialty bodies

PHIL HiVol Coal Bodies are known the world over for their strength, reliability and increased payload. From the Powder River Basin of Wyoming to the Appalachian Mountains of West Virginia and throughout other coal producing regions around the globe, PHIL has pioneered structural technology that is second to none for hauling coal. Often imitated, but never fully duplicated, PHIL HiVol Coal Bodies are the right investment for any coal mine that is serious about productivity.

-

bodies_coal_1.jpg

-

bodies_coal_2.jpg

-

bodies_coal_3.jpg

-

bodies_coal_4.jpg

-

bodies_coal_5.jpg

-

bodies_coal_6.jpg

-

bodies_coal_7.jpg

-

bodies_coal_8.jpg

-

bodies_coal_9.jpg

-

bodies_coal_10.jpg

-

bodies_coal_11.jpg

-

bodies_coal_12.jpg

-

bodies_coal_13.jpg

-

bodies_coal_14.jpg

-

bodies_coal_15.jpg

-

bodies_coal_16.jpg

-

bodies_coal_17.jpg

-

bodies_coal_18.jpg

-

bodies_coal_19.jpg

-

bodies_coal_20.jpg

-

bodies_coal_21.jpg

-

bodies_coal_22.jpg

-

bodies_coal_23.jpg

-

bodies_coal_24.jpg

-

bodies_coal_25.jpg

-

bodies_coal_26.jpg

-

bodies_coal_27.jpg

-

bodies_coal_28.jpg

-

bodies_coal_29.jpg

-

bodies_coal_30.jpg

-

bodies_coal_31.jpg

-

bodies_coal_32.jpg

-

bodies_coal_33.jpg

-

bodies_coal_34.jpg

Bodies - Coal

bodies_coal_1.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_1.jpg

bodies_coal_2.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_2.jpg

bodies_coal_3.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_3.jpg

bodies_coal_4.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_4.jpg

bodies_coal_5.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_5.jpg

bodies_coal_6.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_6.jpg

bodies_coal_7.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_7.jpg

bodies_coal_8.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_8.jpg

bodies_coal_9.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_9.jpg

bodies_coal_10.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_10.jpg

bodies_coal_11.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_11.jpg

bodies_coal_12.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_12.jpg

bodies_coal_13.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_13.jpg

bodies_coal_14.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_14.jpg

bodies_coal_15.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_15.jpg

bodies_coal_16.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_16.jpg

bodies_coal_17.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_17.jpg

bodies_coal_18.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_18.jpg

bodies_coal_19.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_19.jpg

bodies_coal_20.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_20.jpg

bodies_coal_21.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_21.jpg

bodies_coal_22.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_22.jpg

bodies_coal_23.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_23.jpg

bodies_coal_24.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_24.jpg

bodies_coal_25.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_25.jpg

bodies_coal_26.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_26.jpg

bodies_coal_27.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_27.jpg

bodies_coal_28.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_28.jpg

bodies_coal_29.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_29.jpg

bodies_coal_30.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_30.jpg

bodies_coal_31.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_31.jpg

bodies_coal_32.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_32.jpg

bodies_coal_33.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_33.jpg

bodies_coal_34.jpg

https://www.philsystems.com/images/equipment/bodies/coal/bodies_coal_34.jpg

Coal

Coal  Dual-Purpose

Dual-Purpose  Overburden

Overburden  HardRock® / Ore

HardRock® / Ore  Oil Sands®

Oil Sands®  Asymmetrical Underground

Asymmetrical Underground Scrap Steel

Scrap Steel  Hot Slag

Hot Slag  Refuse, Mulch & Bio-Solids

Refuse, Mulch & Bio-Solids  CCP's - Flyash, etc.

CCP's - Flyash, etc.