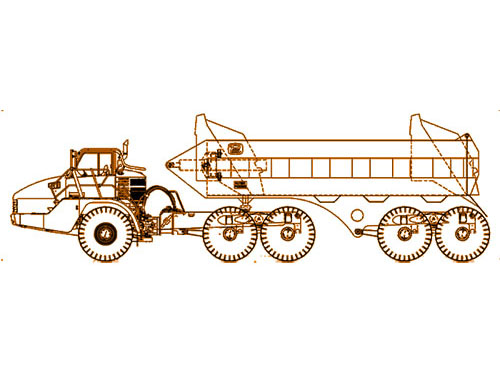

Each PHIL patented Rear Eject HiVol® Trailer is specifically engineered for each client and their unique applications. Whether you dump on the go, handle hard to dump sticky materials, have limited dump clearance, want to increase your payload or just want to dump faster and safer, PHIL's Rear Eject HiVol Trailer's maximize truck utilization for increased productivity. Available for most makes & models of off-highway trucks.

With dumping times that are in line with or better than end-dump bodies, the speed is directly related to the hydraulic wet kit / hydraulic system that is present on the truck, Our Rear Eject Trailer outperforms all other units by forcibly ejecting all materials, even the stickiest, and reduces carryback, all without raising the trailer, keeping its center of gravity constant and low. Our ejector system increases truck stability with a lower load center, allowing trucks to dump in conditions where standard dump trucks would be unstable and unsafe. Dump on downhill slopes, side slopes, and softer underfoot conditions with confidence.

With its easy in-cab controlled operation, our Rear Eject Trailer spreads material as it ejects, reducing dozing and spreading workloads. The ejector trailer employs PHIL's exclusive ejector guides – no rollers – for fast, smooth, low maintenance ejector operation. Its unique flat floor provides complete material shedding extending floor life.

Designed with a simple hydraulic system, one hydraulic cylinder controls the ejector and tailgate offering the fastest stationary or on-the-go dumping, reducing total haul cycle times. And our Rear Eject Body has only one lubrication point that needs greasing just once a year – no other regular maintenance required.

The PHIL Rear Eject Trailer is your ideal choice to handle haulage challenges associated with large quantities of material movement in road construction, steel mill, refuse and mine reclamation on sites where overhead barriers such as trees, power lines, overpasses, pipelines and conveyors inhibit dumping.

PHIL Rear Eject Trailers fit most makes/models of off-highway trucks and applications.

For ADT's

For ADT's For Scrap Steel

For Scrap Steel For Flyash

For Flyash Custom Sized

Custom Sized Rear Ejects

Rear Ejects  For Articulated Haulers

For Articulated Haulers  For Rigid Frame Trucks

For Rigid Frame Trucks  Rear Eject Refuse Bodies

Rear Eject Refuse Bodies  Rear Eject Flyash Bodies

Rear Eject Flyash Bodies  Rear Eject Scrap Steel Bodies

Rear Eject Scrap Steel Bodies  Rear Eject Material Spreader Bodies

Rear Eject Material Spreader Bodies  For Underground

For Underground  Custom Sized Rear Eject Bodies

Custom Sized Rear Eject Bodies  Rear Eject Trailers

Rear Eject Trailers